Project Info

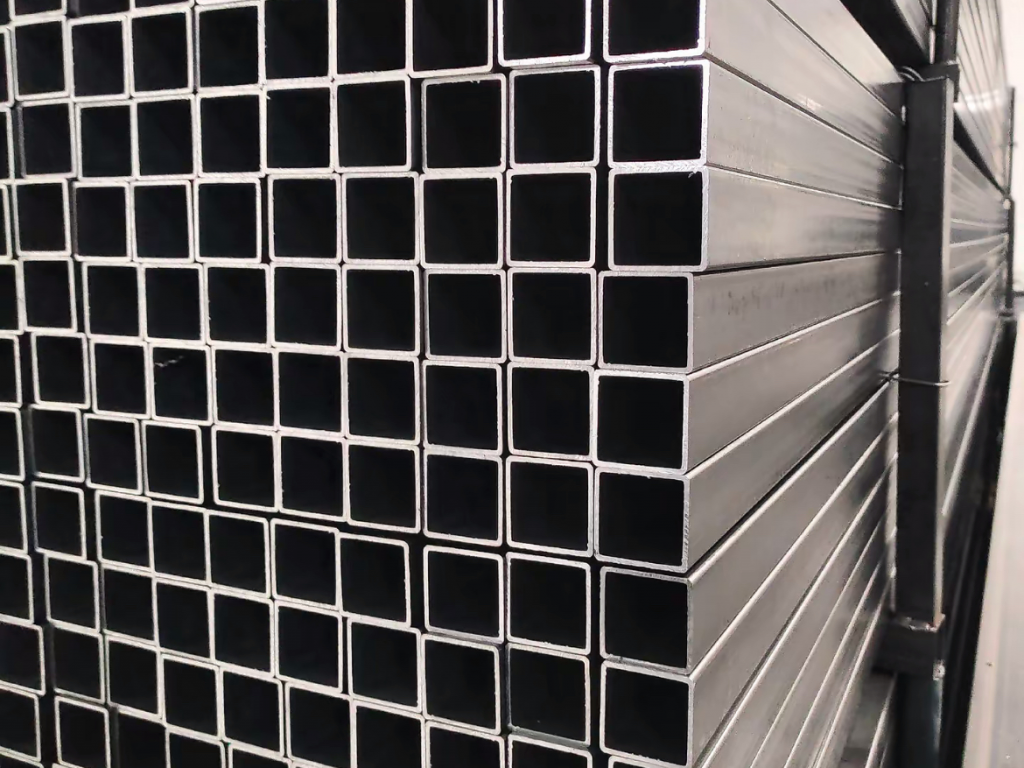

Galvanized square tube

Introduction to galvanized square tube products

1. Product Overview: Galvanized square tube is a type of steel pipe with a square cross-section, which has undergone galvanizing treatment on the surface and has excellent corrosion resistance and aesthetics. Widely used in fields such as construction, machinery manufacturing, furniture, decoration, etc.

2. Main features

Corrosion resistance: The galvanized layer effectively prevents steel pipes from rusting and extends their service life.

High strength: It has high tensile and compressive strength.

Easy to process: Easy to cut, bend, and weld, convenient for construction.

Aesthetic: The galvanized layer gives the steel pipe a shiny appearance, suitable for decorative purposes.

3. Material

Carbon steel: such as Q195 Q235, Suitable for general structural components and decorative purposes.

Low alloy steel, such as Q345, is suitable for applications requiring high strength.

4. Production process

Hot dip galvanizing: Dip the square tube into molten zinc solution to form a uniform galvanized layer, suitable for thick walled pipes.

Electrogalvanizing: Galvanizing the surface of square tubes through electrolytic process, suitable for thin-walled tubes.

5. Application Fields

Architecture: Used for steel structure frames, scaffolding, guardrails, etc.

Mechanical manufacturing: structural components used for mechanical equipment.

Furniture: A frame used for furniture such as tables, chairs, and cabinets.

Decoration: Used for indoor and outdoor decoration, exhibition shelves, etc.

6. Specifications and standards

Section size: 10mm × 10mm to 200mm × 200mm

Wall thickness: 0.8mm to 6.0mm

Length: usually 6 meters, can be customized according to needs

Standards: Complies with international standards such as GB, ASTM, DIN, JIS, etc

7. Quality control

Raw material inspection: Ensure that the material meets the requirements.

Production process control: Strictly monitor each production link.

Finished product inspection: including testing of dimensions, surface quality, galvanized layer thickness, etc.

8. Packaging and Transportation

Packaging: Made of moisture-proof materials to ensure safe transportation.

Transportation: Ensure timely delivery through land, sea, or air transportation.

9. After sales service

Technical support: Provide guidance on selection, installation, and maintenance.

Quality assurance: Provide a warranty period to ensure product quality.