Project Info

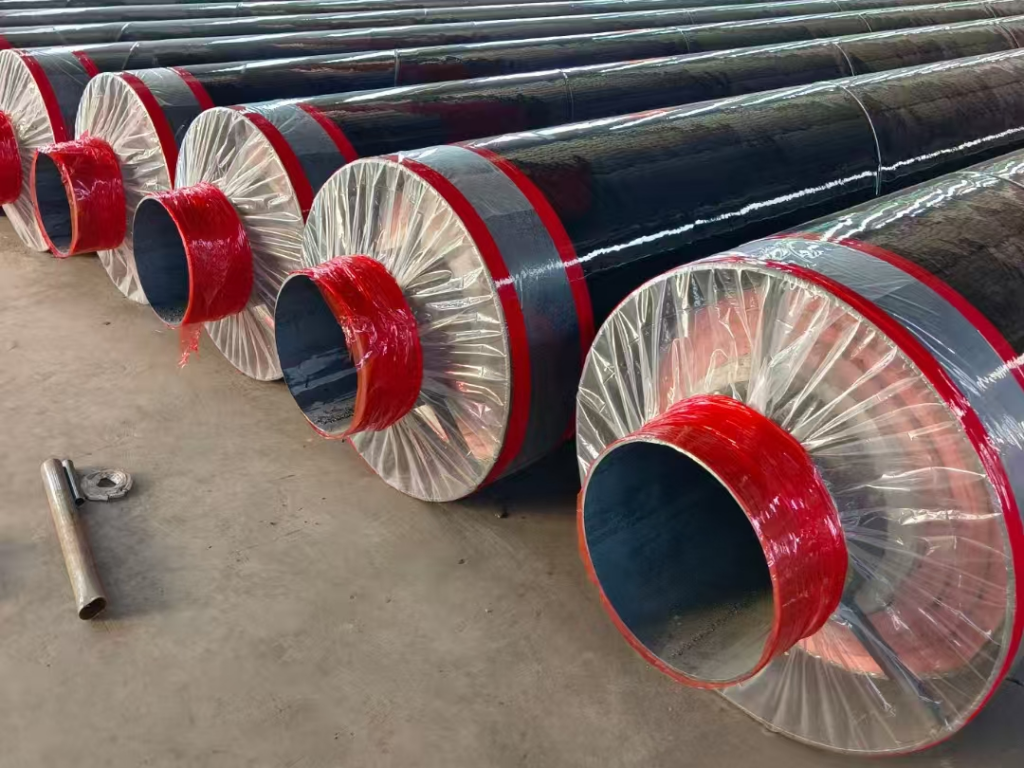

Steel sleeve steel insulated pipeline

Steel sleeve steel insulated pipeline is a type of insulation and cooling engineering pipeline used in industries such as heating, cooling, hot oil transportation, and chemical engineering. It consists of a working steel pipe for conveying media, a glass wool insulation layer, an aluminum foil reflective layer, a stainless steel fastening strap, a sliding guide bracket, an air insulation layer, an outer protective steel pipe, and an outer anti-corrosion layer. This type of pipeline adopts underground direct burial method, without the need for concrete structure. The thermal expansion of the working steel pipe is carried out inside the outer pipe, thereby reducing material costs, shortening the construction period, and ensuring the safety of the heating pipeline.

Steel sleeve steam insulation pipe is composed of an outer protective steel pipe, steel pipe anti-corrosion, insulation layer, and inner working steel pipe combination. Steel sheathed steam composite insulation pipe is suitable for transporting steam or other media below 2.5MPa and 350 degrees Celsius. This product uses steel pipes as the outer protective layer, which has the advantages of high strength, low damage, easy construction and maintenance, and long service life.

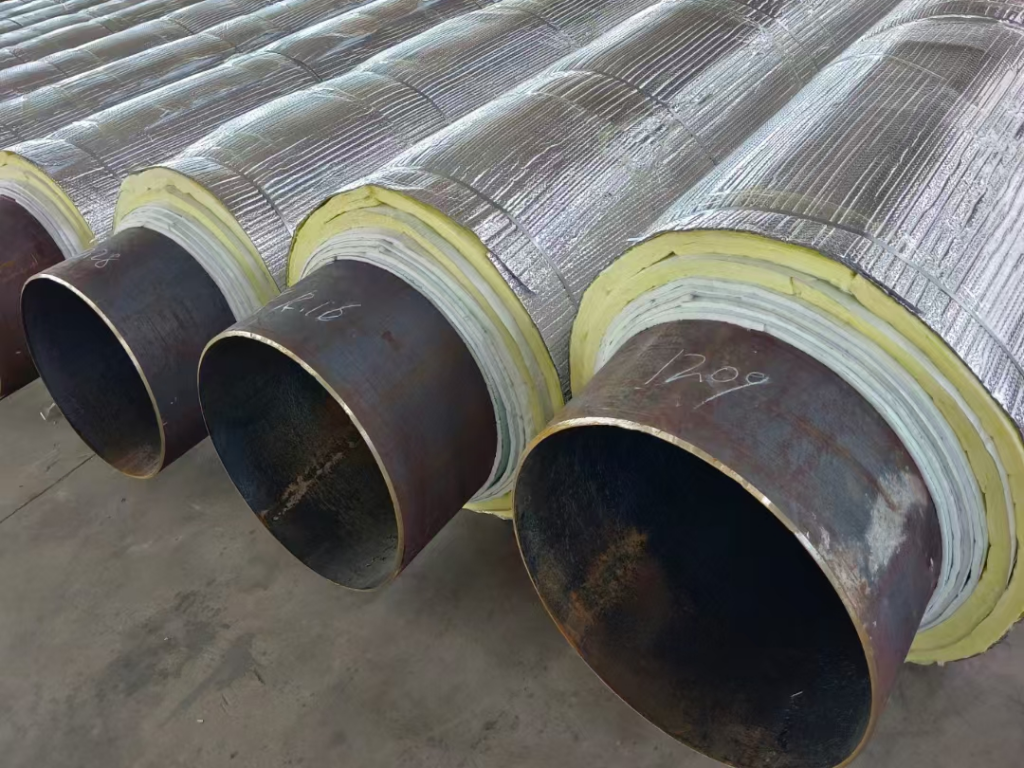

thermal insulation structure

The insulation structure of steel sleeve steel insulation pipe is divided into internal sliding type and external sliding type according to different sliding modes

1. Internal sliding type: The insulation structure consists of a working steel pipe, aluminum silicate, drag reduction layer, microporous calcium silicate, insulation layer, stainless steel fastening steel strip, aluminum foil reflective layer, polyurethane insulation layer, outer steel pipe, and external anti-corrosion layer (basically no longer in use).

2. External sliding type: The insulation structure consists of a working steel pipe, a glass wool insulation layer, an aluminum foil reflective layer, a stainless steel fastening strap, a sliding guide bracket, an air insulation layer, an external protective steel pipe, and an external anti-corrosion layer.

1. Anti corrosion coating: protects the outer steel pipe from corrosive substances, prolongs the service life of the steel pipe.

2. Outer protective steel pipe: protects the insulation layer from groundwater erosion, supports the working pipe and can withstand certain external loads, ensuring the normal operation of the working pipe.

3. Glass wool insulation layer and air insulation layer: Ensure the temperature of the medium and keep the surface of the outer protective pipe at room temperature.

4. Aluminum foil reflective layer: ensure that the organic foam material does not enter the inorganic hard high temperature resistant layer; Reflect some heat from the high-temperature resistant layer.

5. Inorganic hard thermal insulation layer: resistant to high temperature, ensuring the interface temperature between organic thermal insulation layer and foam not to be carbonized.

6. Stainless steel fastening straps and sliding guide brackets: ensure the free movement of the working steel pipe during thermal expansion and contraction.

7. Working steel pipe: Ensure normal flow of conveying medium

characteristic

1. Reduce project costs.

2. Low heat loss, energy-saving.

3. Anti corrosion, good insulation performance, and long service life.

4. Less land occupation, faster construction, and favorable environmental protection.

5. Safe.