Project Info

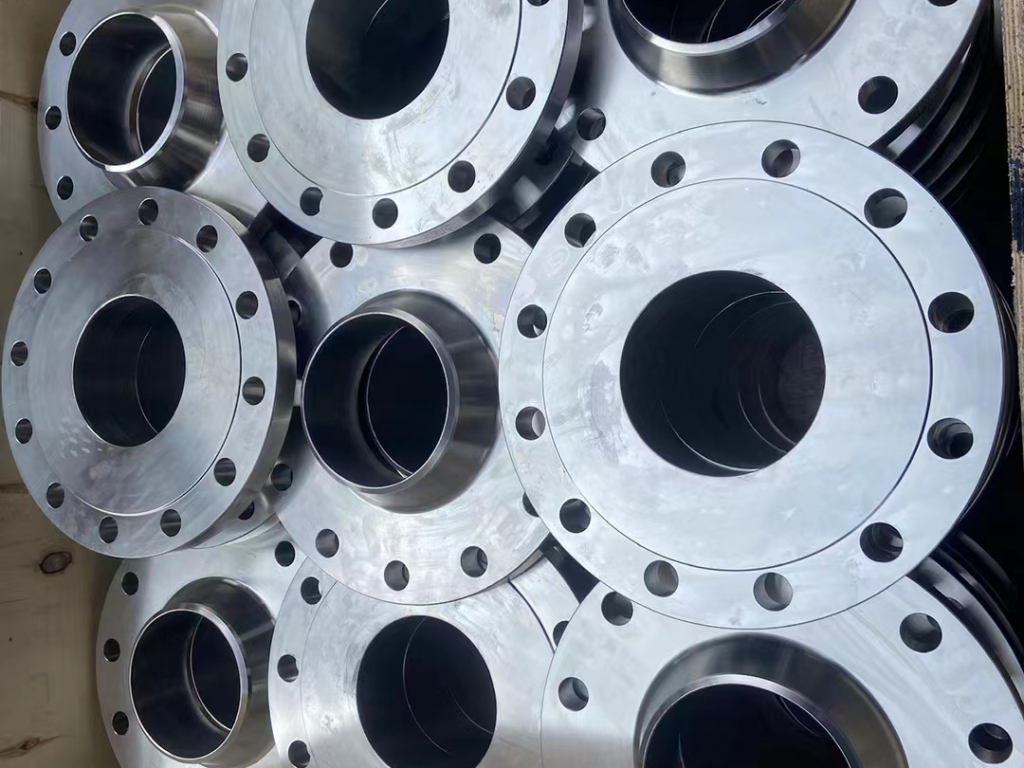

flange

###Introduction to flange products

####1、 Overview of flanges

A flange is a circular mechanical component used to connect pipelines, valves, pumps, and other equipment, achieving system tightness through bolt fastening and gasket sealing. Its core function is to simplify installation, maintenance, and ensure the safety and stability of the fluid delivery system.

—

####2、 Main types and characteristics

1. * * Classified by connection method * *:

-* * Welding flange (WN) * *: neck slope design, high welding strength, suitable for high pressure and high temperature environments (such as petrochemicals and electricity).

-Flat welding flange (SO): welded to the outer wall of the pipeline, economical and practical, suitable for low-pressure and room temperature systems.

-* * Threaded flange (TH) * *: Internal wall threaded connection, no welding required, easy to disassemble, used for low-pressure small-diameter applications.

-Blind flange (BL): A closed pipe end used for system isolation or pressure testing.

2. * * By sealing surface type * *:

-RF (RF): With a circular protrusion and a soft cushion, it has strong versatility.

-Uneven Surface (MFM): The combination of concave and convex surfaces provides a more stringent seal, making it suitable for flammable and explosive media.

-* * Mortise and tenon surface (TG) * *: Precision mortise and tenon structure, used for extreme high pressure or vacuum environments.

—

####3、 Material and Craftsmanship

1. * * Common Materials * *:

-Carbon steel (A105, Q235): High cost performance, suitable for general working conditions.

-Stainless steel (304, 316L): corrosion-resistant, used in the chemical, food and pharmaceutical industries.

-Alloy steel (F11, F22): resistant to high temperature and high pressure, suitable for power plants and boiler systems.

2. * * Manufacturing process * *:

-Forged flange: Excellent mechanical performance, strong impact resistance, suitable for critical high-pressure parts.

-Casting flanges: Low cost, suitable for mass production and non extreme working conditions.

—

####4、 Technical parameters and standards

-* * Nominal diameter (DN) * *: DN15~DN3000 (covering 1/2 inch to 120 inches).

-Pressure rating: PN6~PN250 (or Class 150~2500), meeting different pressure requirements.

-* * International standards * *:

-* * American Standard * *: ANSI B16.5 / B16.47

-* * European Standard * *: EN 1092-1(DIN)

-* * Daily Standard * *: JIS B2220

-* * National standard * *: GB/T 9119

—

####5、 Application Fields

-Energy industry: oil pipelines, natural gas transportation, cooling systems for nuclear power plants.

-Chemical industry: Corrosive medium pipelines (such as acid and alkali) and reactor connections.

-Shipbuilding: seawater cooling system, fuel pipeline sealing.

-* * Municipal engineering * *: Water supply and heating pipelines, sewage treatment equipment.

—

####6、 Quality Control and Certification

-* * Testing process * *: Spectral analysis of raw materials → Dimensional accuracy measurement → Water pressure/air tightness testing → Magnetic particle/ultrasonic testing.

-Certification System: ISO 9001 Quality System, API 6A (Petroleum Industry Specific), CE/PED (EU Pressure Equipment Directive).

—

####7、 Selection and installation suggestions

1. * * Selection points * *:

-Select corrosion-resistant materials based on the characteristics of the medium (such as sulfur resistant materials required for H ₂ S environment).

-Welding flanges should be preferred for high-temperature conditions to avoid leakage caused by thermal expansion and contraction.

2. * * Installation specifications * *:

-The bolts need to be gradually tightened diagonally to ensure even force distribution.

-The gasket material needs to match the medium (such as PTFE acid and alkali resistance, graphite gasket high temperature resistance).

—

####8、 Service and Advantages

-* * Customized Service * *: Supports non-standard size and irregular flange design.

-Quick Delivery: Regular specifications have sufficient inventory, and urgent orders can be shipped within 72 hours.

-* * After sales support * *: Provide technical consultation, on-site installation guidance, and lifetime warranty.

—

Through the above introduction, we are committed to providing customers with highly reliable and multi scenario compatible flange solutions, helping global industrial systems operate efficiently and safely. For detailed parameters or selection support, please contact our engineering team.