Project Info

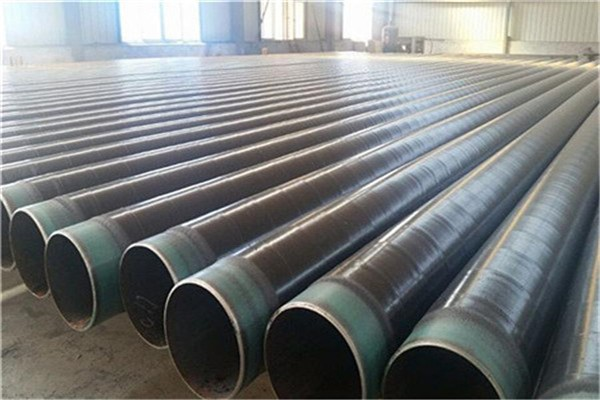

3PE anti-corrosion spiral steel pipe polyethylene three-layer structure protective layer, also known as three-layer PE (3PE), is an advanced anti-corrosion technology introduced from abroad in recent years.

Its full name is fusion bonded epoxy/extruded polyethylene structural protective layer, which consists of the following three layers: the bottom layer is fusion bonded epoxy (≥ 80 μ m); The middle layer is adhesive (170-250 μ m); The surface layer is extruded polyethylene (about 2mm). The total thickness of the protective layer is about 1.8-3.7mm. In the three-layer structure, the main function of the fusion bonded epoxy powder coating is to form a continuous coating film, which is directly bonded to the surface of the steel pipe and has good chemical corrosion resistance and cathodic stripping resistance; Reacts with the active groups of the intermediate layer adhesive to form a chemical bond, ensuring that the overall anti-corrosion layer has good adhesion at higher temperatures.

3PE anti-corrosion spiral steel pipe anti-corrosion structure: layer of epoxy powder (FBE>100um), layer of adhesive (copolymer adhesive) 170-250um, and third layer of polyethylene (PE) 2.5-3.7mm. These three materials are tightly fused together and firmly combined with the steel pipe to form an excellent anti-corrosion layer. 2PE anti-corrosion steel pipe pipeline: The pipeline has a two-layer PE anti-corrosion structure, with a layer of adhesive (AD) and a layer of polyethylene (PE). The two materials are integrated into one, and the thickness of each layer is the same as that of the three-layer PE Thickness: 1.7-2.5 Pipe diameter range: Φ 60~Φ 1420 Execution standard: SY/T0413-2002 Advantages: 3pe anti-corrosion steel pipe has extremely high sealing performance, and long-term operation can greatly save energy, reduce costs, and protect the environment. It has strong corrosion resistance, the construction method is simple and fast, and the service life can reach 30-50 years. PE also has good corrosion and impact resistance under low temperature conditions, with low water absorption rate (less than 0.01%). Simultaneously possessing high epoxy strength, low water absorption of PE, and good flexibility of hot melt adhesive, it has high anti-corrosion reliability.The intermediate layer is usually a copolymer adhesive, which is mainly composed of polyolefin. Currently, ethylene based copolymer adhesives are widely used. The polar functional groups of the copolymer adhesive can react with the epoxy groups of the fusion bonded epoxy powder coating to form hydrogen bonds or chemical bonds, forming a good bond between the intermediate layer and the bottom layer; The non-polar ethylene portion has a good affinity with the surface layer polyethylene, so the intermediate layer also has good bonding performance with the surface layer. The main function of polyethylene surface layer is to provide mechanical protection and anti-corrosion, which is the same as the traditional two-layer structure polyethylene anti-corrosion layer.3PE anti-corrosion spiral steel pipe anti-corrosion structure: layer of epoxy powder (FBE>100um), layer of adhesive (copolymer adhesive) 170-250um, and third layer of polyethylene (PE) 2.5-3.7mm. These three materials are tightly fused together and firmly combined with the steel pipe to form an excellent anti-corrosion layer. 2PE anti-corrosion steel pipe pipeline: The pipeline has a two-layer PE anti-corrosion structure, with a layer of adhesive (AD) and a layer of polyethylene (PE). The two materials are integrated into one, and the thickness of each layer is the same as that of the three-layer PE Thickness: 1.7-2.5 Pipe diameter range: Φ 60~Φ 1420 Execution standard: SY/T0413-2002 Advantages: 3pe anti-corrosion steel pipe has extremely high sealing performance, and long-term operation can greatly save energy, reduce costs, and protect the environment. It has strong corrosion resistance, the construction method is simple and fast, and the service life can reach 30-50 years. PE also has good corrosion and impact resistance under low temperature conditions, with low water absorption rate (less than 0.01%). Simultaneously possessing high epoxy strength, low water absorption of PE, and good flexibility of hot melt adhesive, it has high anti-corrosion reliability.

Project Information

- Project Category: Rubix carabil tower

- Clients: David Malan

- Project Date: 25 June, 2024

- Avenue End Date: 08 July, 2024

- Locations: NewYork – 4648 Rocky, USA

- Price After: $10 Million