Project Info

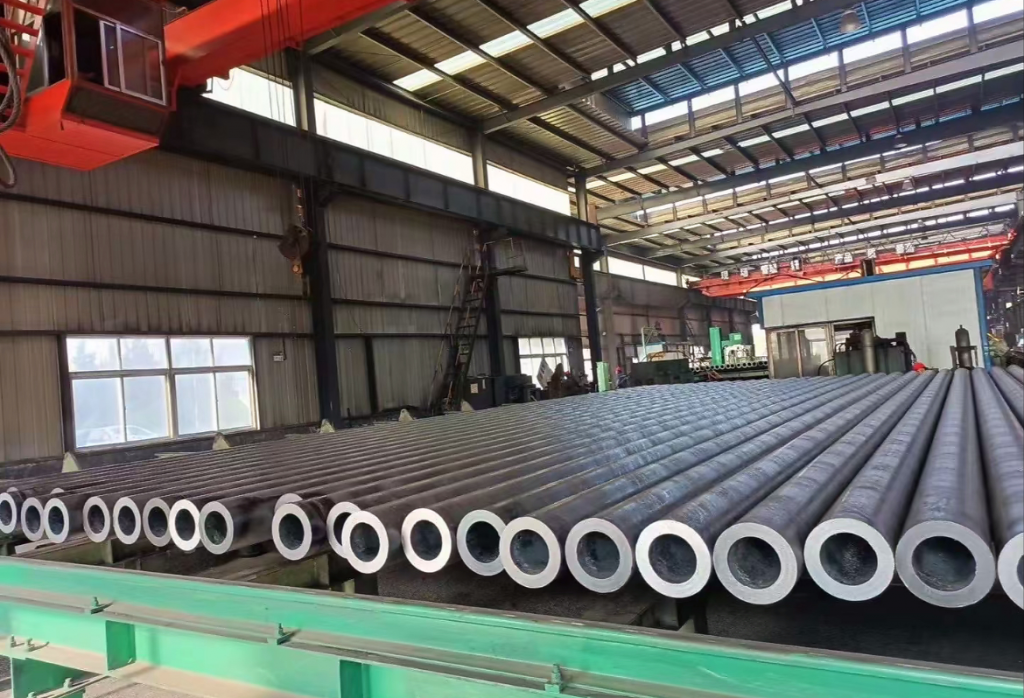

Seamless steel pipe

Seamless steel pipe product introduction

1. Product Overview

Seamless pipe is a type of steel pipe manufactured through hot rolling, cold rolling, or cold drawing processes, named after its lack of welds. Widely used in fields such as petroleum, natural gas, chemical, power, and machinery manufacturing.

2. Main features

High strength: Seamless pipes have high tensile and compressive strength.

Corrosion resistance: Stainless steel, alloy steel and other materials can be selected according to needs to enhance corrosion resistance.

High precision: High dimensional accuracy, suitable for precision equipment.

Good sealing performance: No welds, excellent sealing performance, suitable for high-pressure environments.

3. Material

Carbon steel: such as 20 # and 45 # steel, suitable for general structural components and fluid transportation.

Stainless steel: such as 304 and 316, suitable for corrosive environments.

Alloy steel: such as 15CrMo, 12Cr1MoV, suitable for high temperature and high pressure environments.

4. Production process

Hot rolling: suitable for large-diameter and thick walled pipes, with high production efficiency.

Cold rolling: suitable for small-diameter and thin-walled pipes, with high dimensional accuracy.

Cold drawing: Suitable for pipes with high precision and high surface quality requirements.

5. Application Fields

Oil and natural gas: used for oil well pipes, transmission pipes, etc.

Chemical industry: used for corrosion-resistant pipelines.

Electricity: used for boiler tubes, superheater tubes, etc.

Mechanical manufacturing: used for precision components such as hydraulic cylinders and air cylinders.

6. Specifications and standards

Outer diameter: 6mm to 1200mm

Wall thickness: 0.5mm to 120mm

Length: Customizable according to requirements

Standards: Complies with international standards such as GB, ASTM, DIN, JIS, etc

7. Quality control

Raw material inspection: Ensure that the material meets the requirements.

Production process control: Strictly monitor each production link.

Finished product inspection: including testing of dimensions, surface quality, mechanical properties, etc.

8. Packaging and Transportation

Packaging: Using rust proof oil and moisture-proof materials to ensure safe transportation.

Transportation: Ensure timely delivery through land, sea, or air transportation.

9. After sales service

Technical support: Provide guidance on selection, installation, and maintenance.

Quality assurance: Provide a warranty period to ensure product quality.

Seamless pipes have become an important material in the industrial field due to their excellent performance and wide applications. We are committed to providing high-quality products and services to meet customer needs.