Project Info

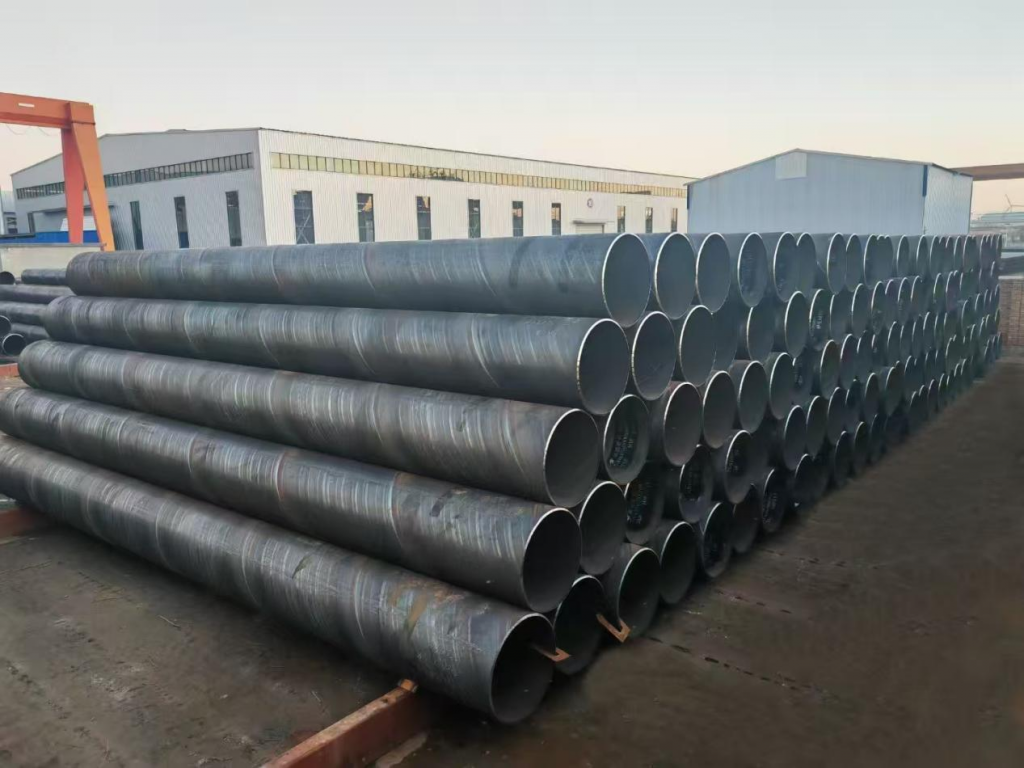

Spiral steel pipe

The specifications and models of spiral steel pipes are usually divided based on their outer diameter, wall thickness, length, and material. The following is a detailed description of common specifications and models of spiral steel pipes:

1. Outer diameter (OD): Spiral steel pipes have a wide range of outer diameters, and common specifications include:

-Small caliber: 219mm, 273mm, 325mm

-Medium caliber: 426mm, 530mm, 630mm

-Large caliber: 720mm, 820mm, 1020mm, 1220mm, 1420mm, 1620mm, 1820mm, 2020mm, 2520mm, etc

2. Wall thickness (WT): The wall thickness is usually selected according to usage requirements, with common wall thicknesses ranging from 6mm to 25mm, and special wall thicknesses can be customized.

3. Length: The standard length is usually 6 meters, 9 meters, 12 meters, and can also be customized according to customer needs.

4. Material: Spiral steel pipes come in various materials, including:

– Q235A, Q235B, Q235C, Q235D

– Q345B, Q345C, Q345D

– L245, L290, L360, L415, L450, L485

– X42, X46, X52, X56, X60, X65, X70, X80

5. Execution standards: The manufacturing and execution standards for spiral steel pipes include:

-GB/T 9711-2017 (Steel Pipe for Petroleum and Natural Gas Industry)

-GB/T 3091-2015 (Welded Steel Pipes for Low Pressure Fluid Transport)

-API SPEC 5L (Pipeline Steel Pipe Specification)

-SY/T 5037-2018 (Spiral submerged arc welded steel pipes for ordinary fluid transport pipelines)

-ASTM A53, ASTM A252, ASTM A500, ASTM A671, ASTM A672, etc

6. Application: Spiral steel pipes are widely used in pipeline transportation systems in fields such as petroleum, natural gas, water, coal gas, chemical, power, and construction.

7. Surface treatment: According to the usage environment and customer needs, spiral steel pipes can be treated with anti-corrosion treatment. Common ones include:

-Epoxy coal tar anti-corrosion

-3PE anti-corrosion (three-layer polyethylene)

-FBE anti-corrosion (fusion bonded epoxy powder)

-Internal and external plastic coating

8. Special requirements: According to the specific requirements of the engineering project, spiral steel pipes can also undergo non-destructive testing (such as ultrasonic, radiographic, magnetic particle, etc.), hydrostatic testing, chemical composition analysis, mechanical performance testing, etc.

When selecting spiral steel pipes, it is necessary to comprehensively consider factors such as specific usage environment, conveying medium, pressure requirements, etc., to ensure that the selected steel pipes comply with relevant standards and specifications.