Project Info

Straight Seam Steel Pipe

Straight Seam Steel Pipe

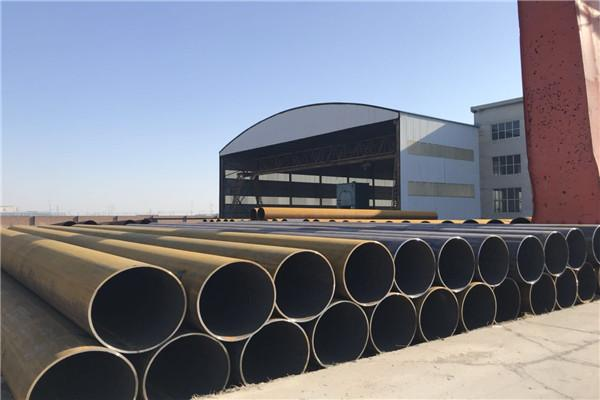

Introduction to Straight Seam Steel Pipe Products

**1、 Product Overview**

Straight seam steel pipe is a steel pipe made by bending steel plates or steel strips into shape and welding them in a straight line direction. The weld seam is straight, hence the name ‘straight seam steel pipe’. Straight seam steel pipes are widely used in fields such as petroleum, natural gas, chemical, power, construction, and water supply. They are important materials for transporting fluids, gases, and structural support.

**2、 Product classification**

1. * * Classified by production process * *:

-High frequency straight seam welded pipe (ERW): using high-frequency resistance welding technology, suitable for low-pressure fluid transportation.

-Submerged arc welded straight seam steel pipe (LSAW): Adopting the submerged arc welding process, it is suitable for high-pressure and large-diameter pipelines.

-Double sided submerged arc welded straight seam steel pipe (DSAW): Double sided welding, higher strength, suitable for large-scale projects.

2. * * Classified by purpose * *:

-Straight seam steel pipe for fluid transportation: used for transporting media such as water, oil, and gas.

-Structural straight seam steel pipe: used for supporting structures such as buildings, bridges, and machinery.

-Straight seam steel pipes for low-pressure boilers: used for the manufacturing and maintenance of low-pressure boilers.

-Straight seam steel pipes for pipelines: used for long-distance transportation of oil and natural gas.

**3、 Product Features**

1. High strength: Made of high-quality steel, it has good compressive and tensile properties.

2. High welding quality: Advanced welding technology is used to ensure uniform and firm welds, ensuring the sealing of the pipeline.

3. * * Diverse specifications * *: Steel pipes with different diameters, wall thicknesses, and lengths can be customized according to customer needs.

4. Strong corrosion resistance: can undergo internal and external anti-corrosion treatment to extend its service life.

5. * * Easy installation * *: Straight seam steel pipes are lightweight, easy to connect, and have high construction efficiency.

**4、 Product specifications**

1. * * Diameter range * *: Usually from Φ 20mm to Φ 2000mm, special specifications can be customized.

2. Wall thickness range: generally 1.0mm to 50mm, choose according to usage needs.

3. * * Length Range * *: Standard lengths are 6m, 9m, 12m, and can also be customized according to customer needs.

4. * * Material * *: Common materials include Q235, Q345, 20 #, 16Mn, L245, L290, X42-X80, etc.

**5、 Production process**

1. * * Raw material preparation * *: Select high-quality steel plates or strips for surface treatment.

2. * * Forming * *: Using a forming machine to bend steel plates or strips into a circular tube shape.

3. Welding: High frequency resistance welding (ERW) or submerged arc welding (SAW) processes are used for welding.

4. * * Weld seam treatment * *: Polish and trim the weld seam to ensure a smooth surface.

5. * * Testing * *: Conduct ultrasonic testing, X-ray testing, hydrostatic testing, etc. to ensure product quality.

6. * * Anti corrosion treatment * *: Conduct internal and external coating anti-corrosion treatment according to requirements (such as epoxy resin, 3PE, etc.).

**6、 Application Fields**

1. Oil and natural gas transportation: A pipeline used for long-distance transportation of oil and natural gas.

2. * * Construction Engineering * *: Used for building structural support, scaffolding, etc.

3. * * Water Supply Engineering * *: Used for urban water supply and drainage pipelines.

4. * * Chemical industry * *: Used for transporting chemical media.

5. * * Power industry * *: used for transporting steam, cooling water, etc.

6. * * Mechanical Manufacturing * *: Used for manufacturing mechanical components, equipment brackets, etc.

**7、 Quality Assurance**

1. Raw material control: Select high-quality steel that meets national standards.

2. Production process control: Advanced production equipment and processes are used to ensure product consistency.

3. * * Testing methods * *: Each batch of products undergoes strict testing, including size inspection, mechanical performance testing, non-destructive testing, etc.

4. * * Certification Standards * *: The product complies with domestic and international standards such as GB/T 3091, GB/T 9711, API 5L, ASTM A53, etc.

**8、 After sales service**

1. * * Technical Support * *: Provide technical services such as product selection and installation guidance.

2. * * Quality Assurance * *: Provide product quality assurance to ensure worry free use for customers.

3. * * Customized Services * *: Provide personalized customized services according to customer needs.

4. * * Logistics Delivery * *: Provide efficient logistics delivery services to ensure timely delivery of products.

**9、 Summary**

Straight seam steel pipes have become an indispensable and important material in modern industry due to their excellent performance, diverse specifications, and wide range of applications. We are committed to providing customers with high-quality straight seam steel pipe products and professional services, meeting the needs of different fields, and assisting in engineering construction and social development.